German Advanced Technologies is a leader in sustainable innovation, dedicated to developing disruptive solutions that address global challenges.

With a focus on proven research and environmentally conscious design, we specialize in the wholesale of products that drive efficiency, durability, and quality, while providing the highest level of supportive engineering services.

Hydrophobic

Frost Resistant

Heavy Duty Load Bearing

High-Performance Additive

About Us

Engineering with Purpose

German Advanced Technologies is an R&D-driven company specializing in high-performance infrastructure solutions that address real-world challenges. Our products are engineered to outperform conventional materials while minimizing environmental and logistical impact.

We focus on technologies that not only meet today’s industrial demands but also reduce reliance on outdated, carbon-intensive construction methods and materials. Every solution is developed through rigorous testing, certified production standards, and field-validated performance.

From Lab to Scalable Solutions

Every technology developed by us has a strict focus on real-world applicability, combining laboratory precision with operational reliability. Our team includes scientists, engineers, and domain specialists who turn advanced materials science into deployable, industrial-grade systems.

Whether it’s in construction, environmental remediation, or energy infrastructure, we ensure each solution is scalable, certifiable, and optimized for cost-performance across diverse use cases.

Sustainability as an Engineering Principle

At German Advanced Technologies, sustainability is a baseline requirement - not a branding claim. We design all technologies to reduce environmental impact while solving long-standing industry inefficiencies.

From emissions and waste to logistical overreach and material overuse, we target non-optimal systemic processes with high-performance, eco-conscious alternative solutions. Several new products are in development that follow this same principle: replace outdated methods with leaner, cleaner, and smarter options - not only in infrastructure, but across multiple sectors facing urgent transformation demands.

About

The Revolutionary Soil Stabilization Solution

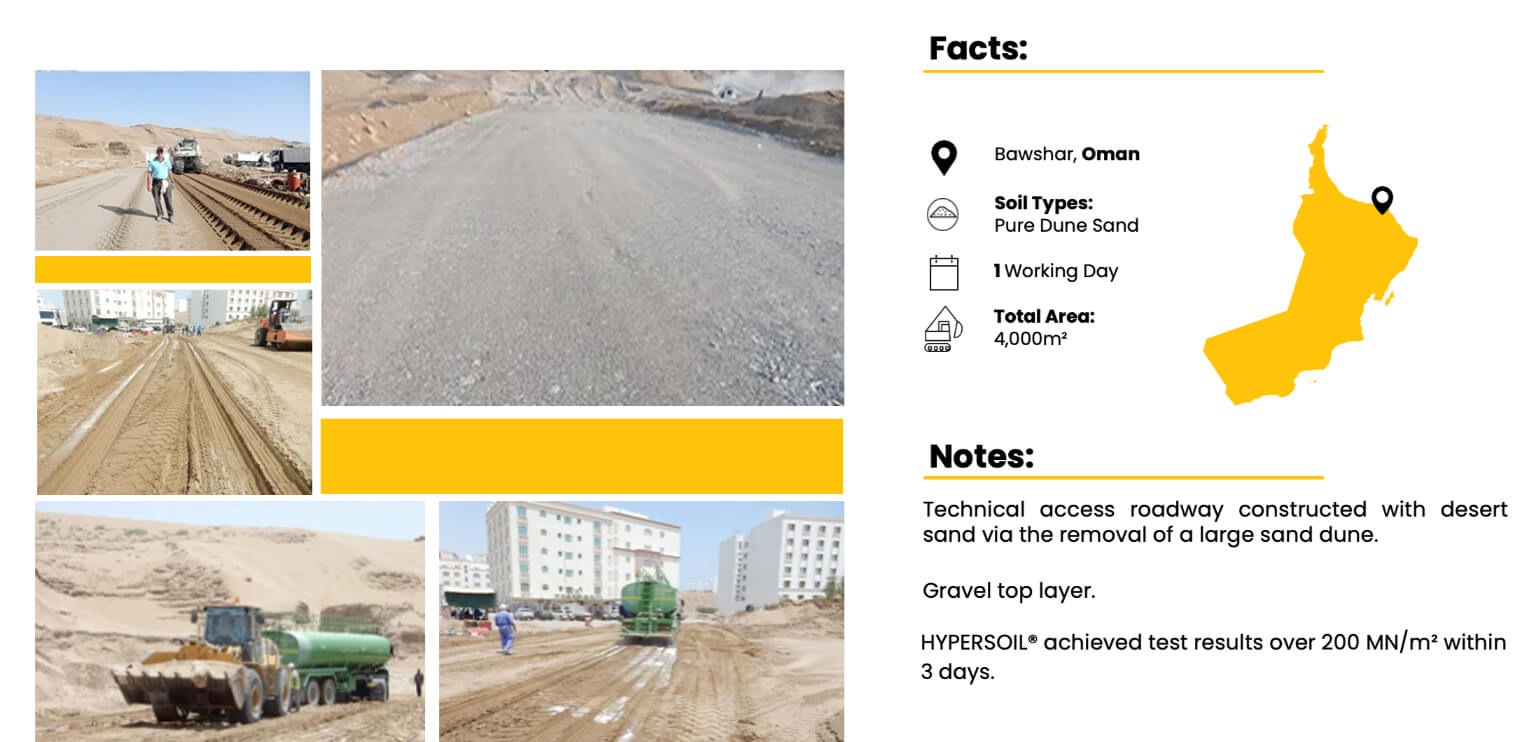

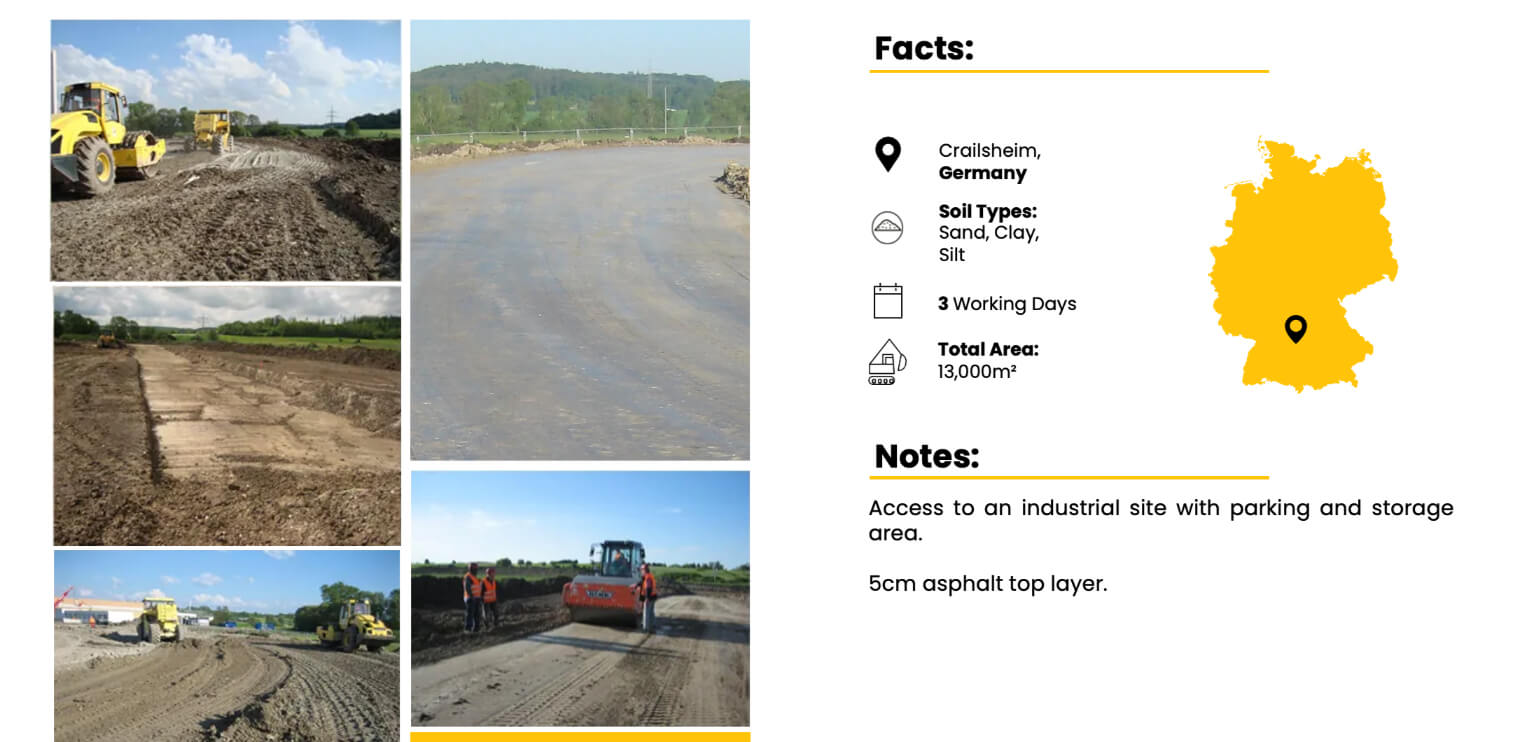

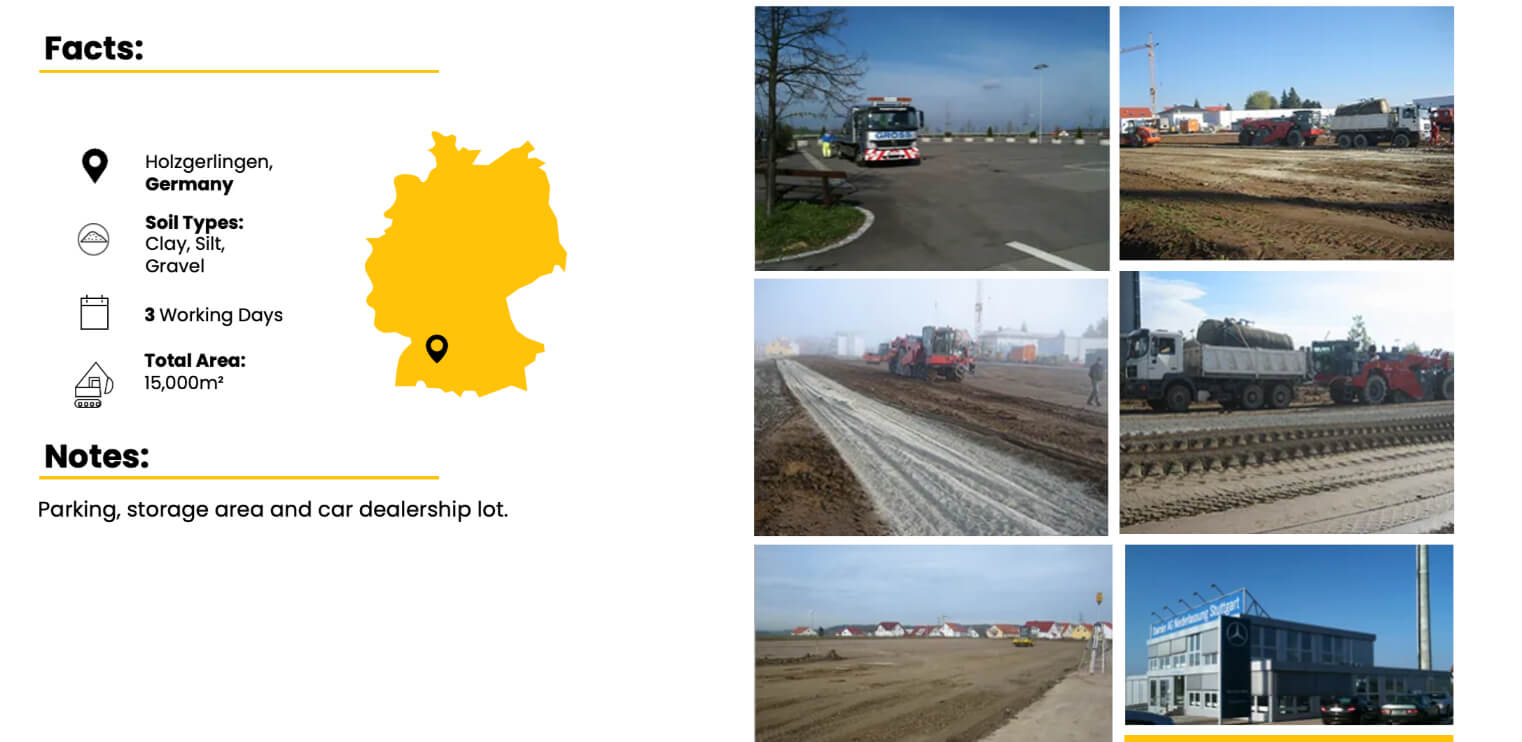

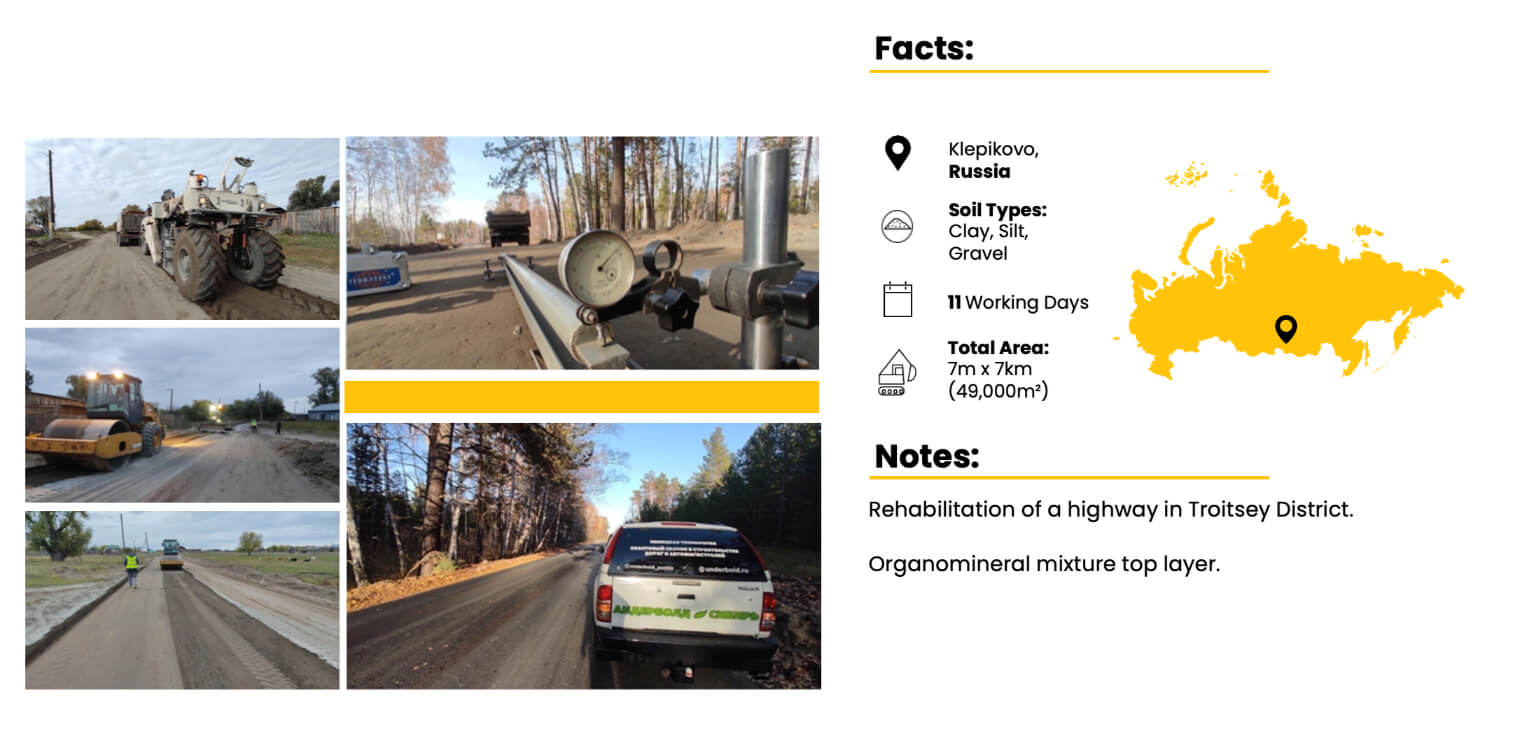

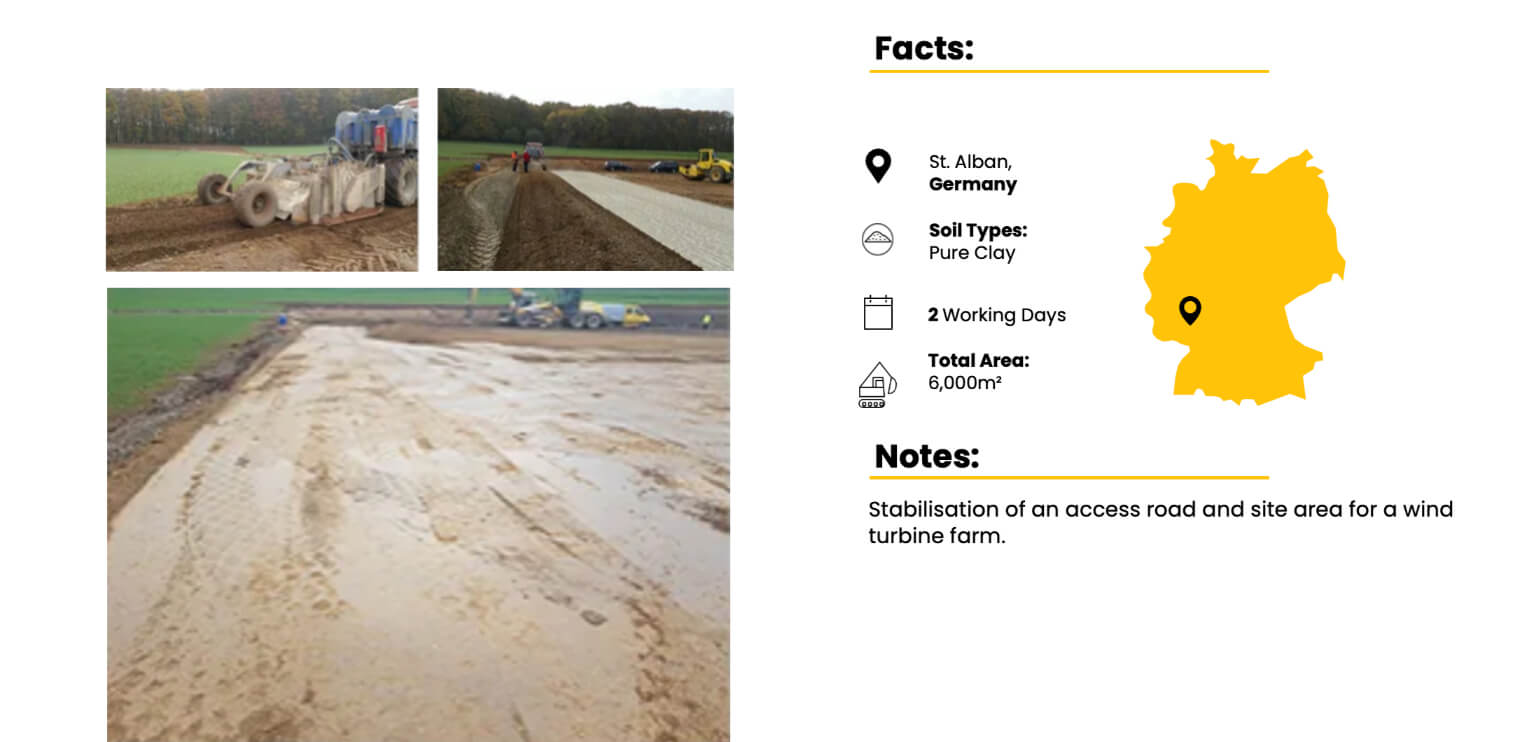

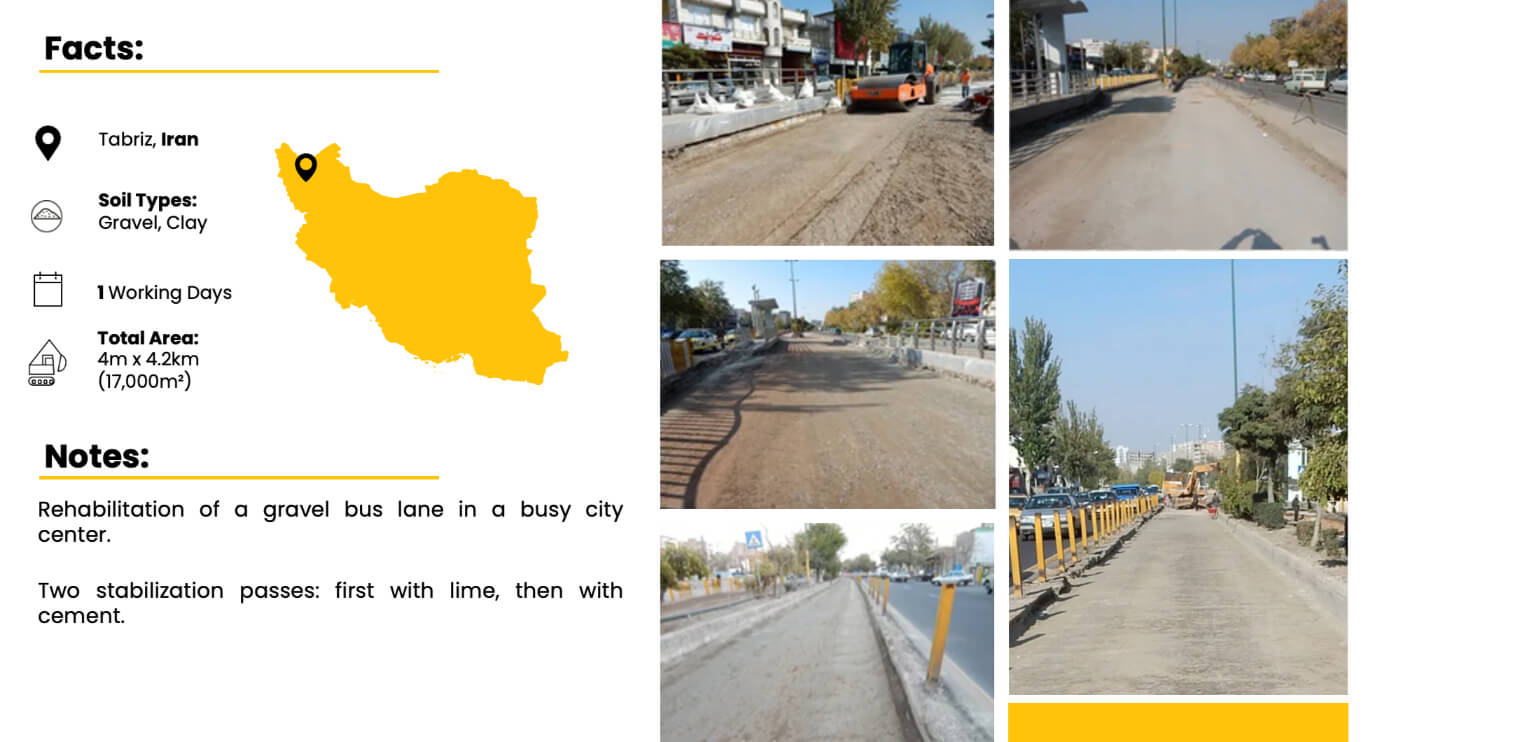

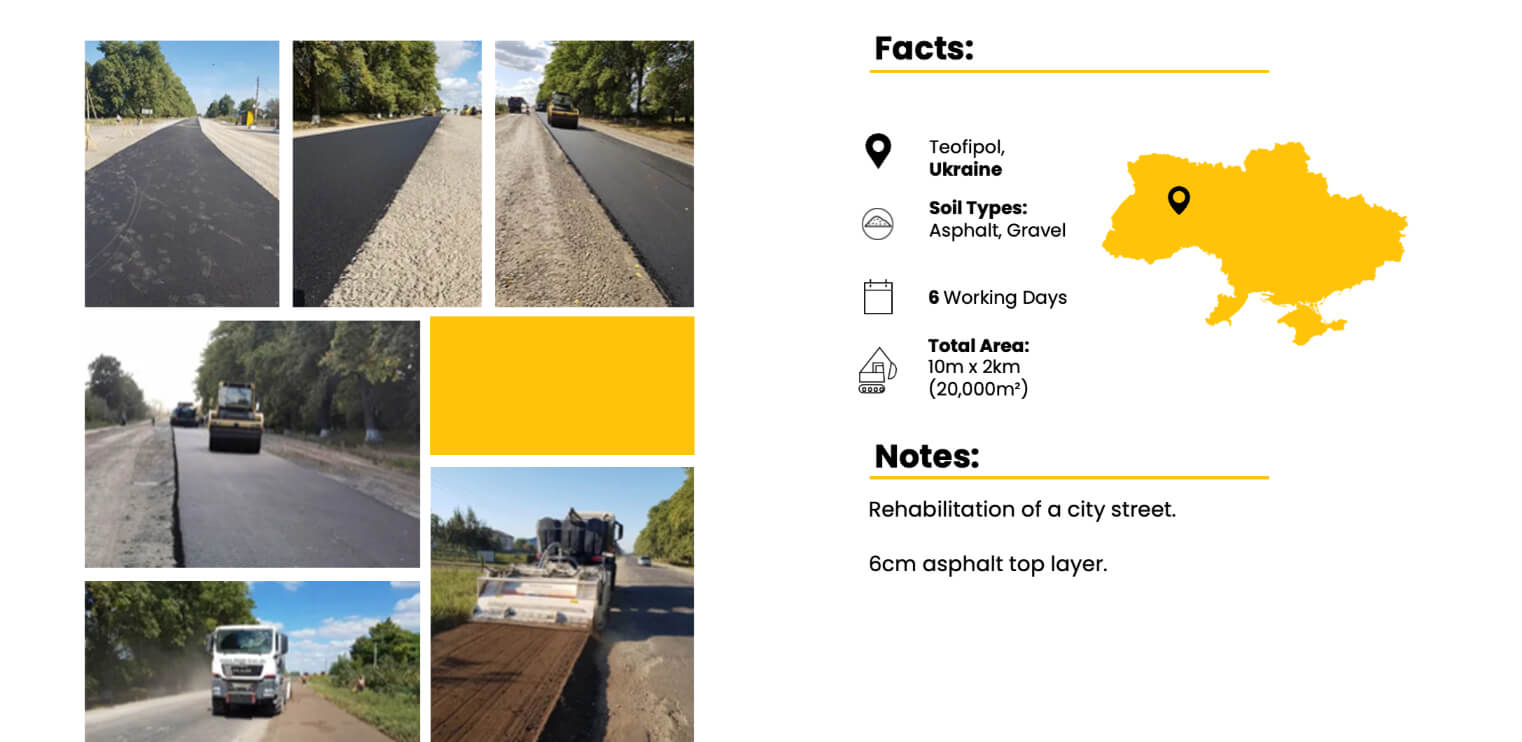

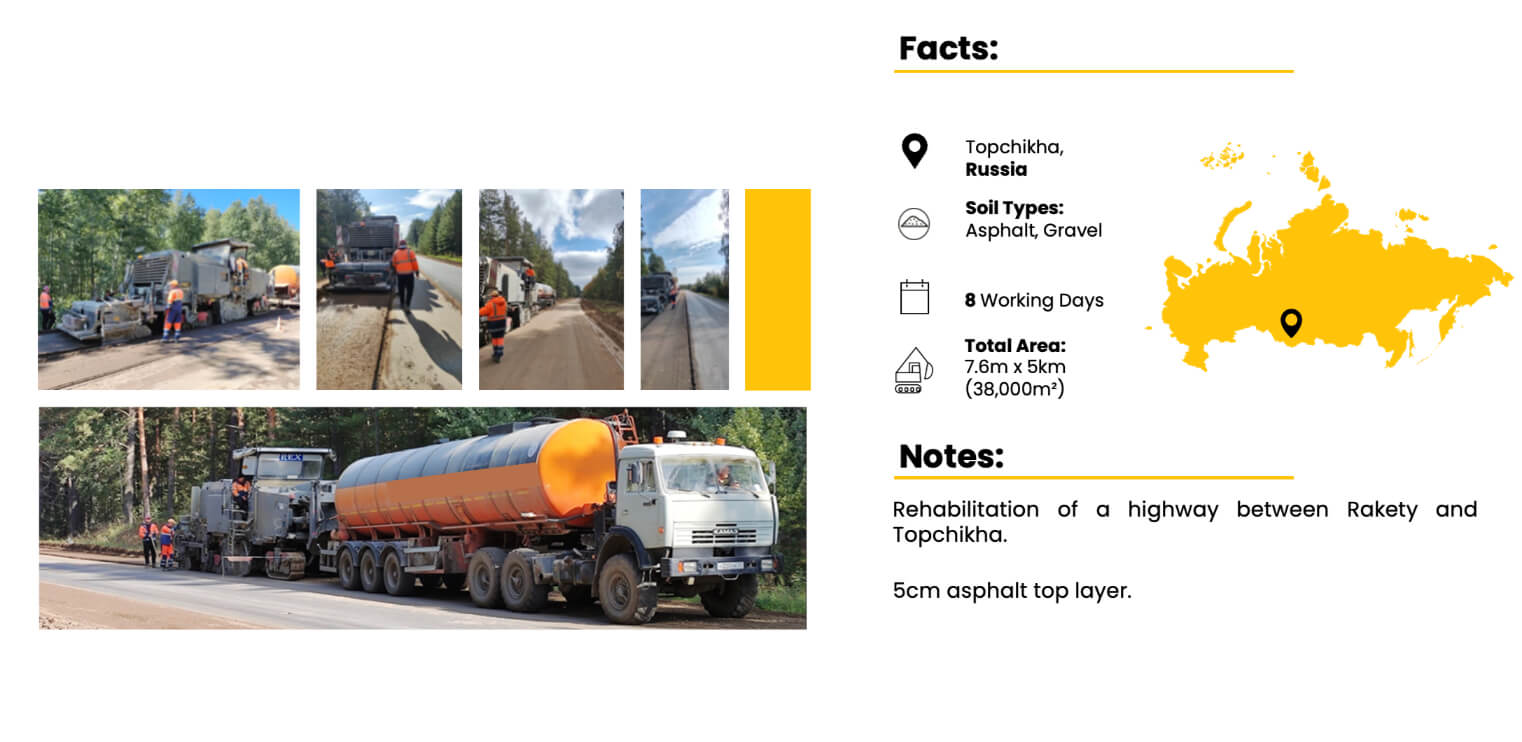

HYPERSOIL® is a water-based, solvent-free wax emulsion engineered specifically for soil stabilization in road and surface construction. Developed and manufactured in Germany since 1995, using renewable energy and sustainably sourced organic raw materials, HYPERSOIL® embodies German Advanced Technologies’ commitment to quality and innovation in over 30 projects worldwide, while being ecologically safe.

Nanotech Innovation

By combining advanced nanotechnology and our simple, standard-aligned, proprietary construction method, HYPERSOIL® binds microscopic soil particles at the nano-level which are then encapsulated in a hydraulic binder. This groundbreaking process achieves extraordinary compressive strengths, resulting in a high load-bearing capacity and an exceptional modulus of elasticity.

The stabilized superstructure becomes hydrophobic, offering full protection against frost and significantly reducing micropores. This design essentially eliminates the possibility of cracks, drastically reducing the need for maintenance over time.

One of HYPERSOIL®’s most remarkable features is its versatility. It can treat all soil types, from salty beach sand and high-moisture clay to contaminated or toxic soils. By permanently immobilizing hazardous materials, HYPERSOIL® prevents them from impacting groundwater or the surrounding environment, making it a sustainable and eco-friendly solution for complex soil stabilization challenges, in climate ranges from -50°C to +50°C.

Efficiency and Cost-Effectiveness

HYPERSOIL®’s mix-in-place system revolutionizes the road construction process by using in situ materials, eliminating the logistical needs to excavate or haul soil to and from construction sites. With HYPERSOIL®, the machinery and personnel required for road construction is reduced to five. Project completion time is reduced by up to 80% when compared to traditional construction, completing in 2 days what is conventionally achieved in 10.

These efficiencies and further knock-on effects translate to project cost reductions of 20-50%, making HYPERSOIL® not only an environmentally sustainable solution but also a highly economical choice for large and small-scale infrastructure projects.

Conventional vs.

VS.

VS.

Advantages of

Frost & Heat Resistant

High load bearing

High Compressive Strength

Hydrophobic

Massive Time Savings

Less machinery and personnel

Massive Cost Savings

Eco-friendly

No Soil Disposal Logistics

All soil types treatable

ISO 9001:2015 manufacturing in Germany

30+ Projects Worldwide

Up to 90% CO2 Savings

Construction Method with

1. First Recycling Pass

HYPERSOIL®–water mixture is milled into the existing soil using a recycler.

2. First Compaction

The treated soil is pre-compacted for passability and initial particle encapsulation.

3. Spreading Binder

A hydraulic binder layer (i.e. cement) is distributed onto the treated soil.

4. Second Recycling Pass

The hydraulic binder is milled into the treated soil and compacted once more.

5. Grading

Leveling to the desired gradient.

6. Final Compaction

Final compaction of the subsoil. Residual moisture is pushed out of the structure.

Frequently Asked Questions

What is HYPERSOIL®?

HYPERSOIL® is a high-performance soil stabilization additive used with cement or lime to strengthen native soil for roads, airstrips, industrial surfaces, and more.

Is it a replacement for cement or lime?

No. HYPERSOIL® must always be used in combination with cement and/or lime. It enhances their effect, reduces the required quantity, and accelerates curing.

How is HYPERSOIL® applied on-site?

The HYPERSOIL®-water solution is milled into the existing soil using a recycler to a depth of ~40 cm. After initial compaction and resting, cement is added and incorporated. Final compaction and grading complete the process.

What kind of performance can I expect?

- CBR: 280% after just 3 days (depending on soil type)

- Compressive strength: ~3.5+ N/mm²

- Load-bearing: ~300+ MN/m²

- Ev² modulus: Typically 150–600+ MN/m²

- Frost resistance: Up to –50°C

- Water resistance: Hydrophobic and durable

What soils can be treated with HYPERSOIL®?

Almost all soils: clay, sand, silt, loam, pure dune sand, salty beach sand, toxic soils and mixed compositions. Soils must have neutral pH (or be improved to achieve neutral pH) and under 3% organic content to work with HYPERSOIL®.

What equipment is required?

Just five machines: a recycler, roller compactor, water truck, cement spreader, and grader. No excavation, no haulage of soil.

How fast is the construction process?

HYPERSOIL® can reduce project time by up to 80% compared to traditional methods, thanks to its mix-in-place process and rapid curing. An average of 4,000 m²/day can be expected from one work column.

Is this cost-effective?

Yes. The faster process, reduced material transport & quantities, and long-term durability result in at least 20% total savings over conventional methods and up to 50% for larger projects. Maintenance and earthworks costs are cut almost entirely.

What is the environmental impact?

CO₂ emissions can be reduced by up to 90% due to the use of in-situ materials and fewer machines on-site. Additionally, HYPERSOIL® is manufactured with renewable materials, using renewable energy. It is non-toxic and does not leach into the surrounding environment, once installed.

How much additive is needed per m²?

Roughly 300ml worth of HYPERSOIL®, plus about 25 kg of cement and 30 liters of water per square meter. 1 Liter of HYPERSOIL® can stabilise roughly 3 m² of soil.

Can it be used in wet or flood-prone areas?

Yes. HYPERSOIL® is hydrophobic and remains stable in high-moisture or flood-prone environments, as long as the underlying soil bearing capacity is not compromised and the initial site preparation was done to the correct standards.

What is the curing time?

Initial strength is achieved after 12 hours, with full performance often measurable within 3 days.

Does it work in desert or sandy terrain? What about low temperature conditions?

Yes. It has been successfully used in desert environments and on loose sandy soils, especially where traditional methods fail.

Due to its hydrophobic effect, HYPERSOIL® is ideally suited for and has consistently performed in cold climate latitudes.

What are typical use cases?

- Roads & highways

- Airstrips and helipads

- Logistic hubs & ports

- Rail embankments

- Mining and agriculture roads

- Temporary or permanent heavy-use areas

- Farms and ranches

- Military bases

- Commercial and industrial real estate developments

- Building pads

- Solar parks & windfarms

How do I use HYPERSOIL®?

You will be provided a comprehensive construction manual with the simple proprietary construction method and calculations for the various material ratios

Where is HYPERSOIL® produced and shipped from?

It is produced and shipped from our industry-leading manufacturing partner’s headquarters in Germany.

Latest Posts

Single Post Design

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

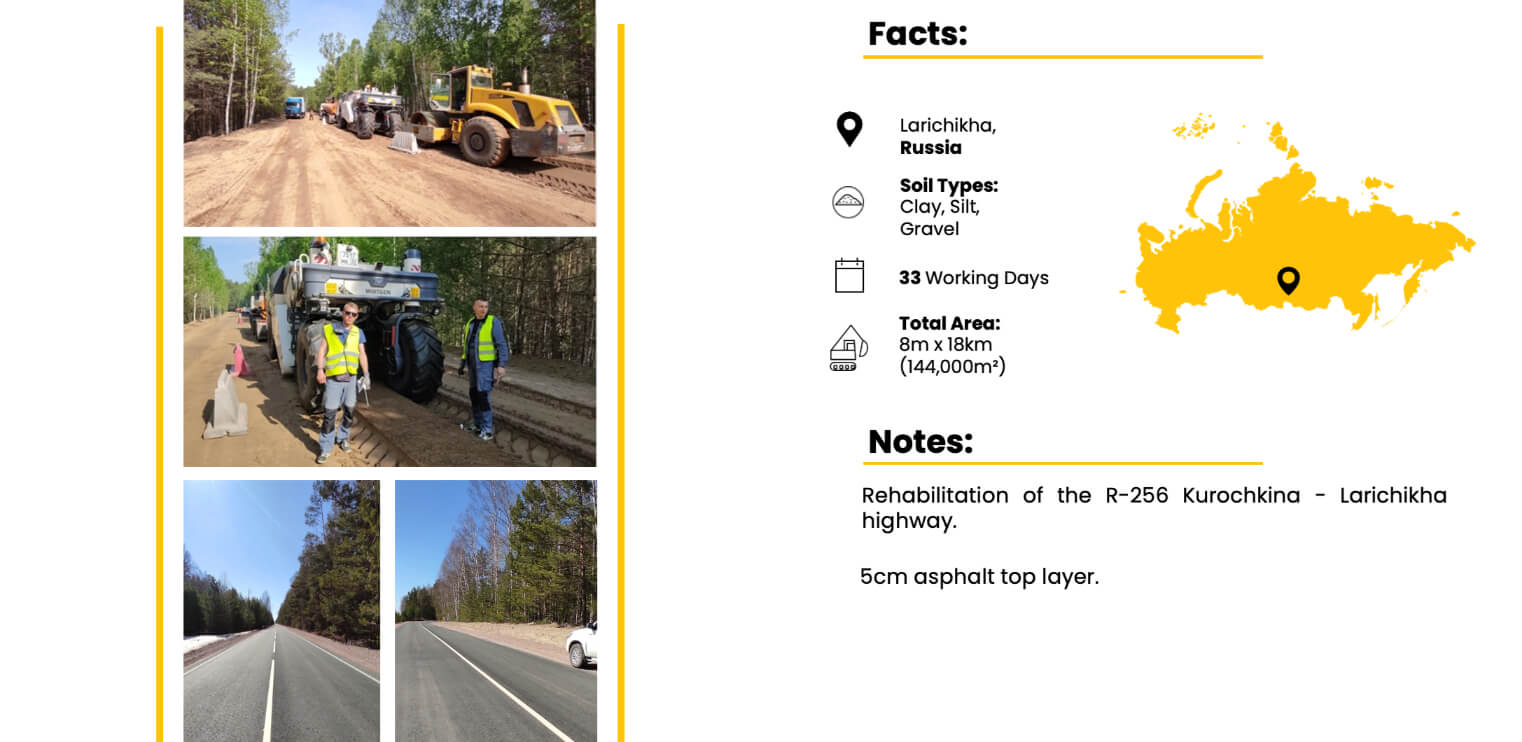

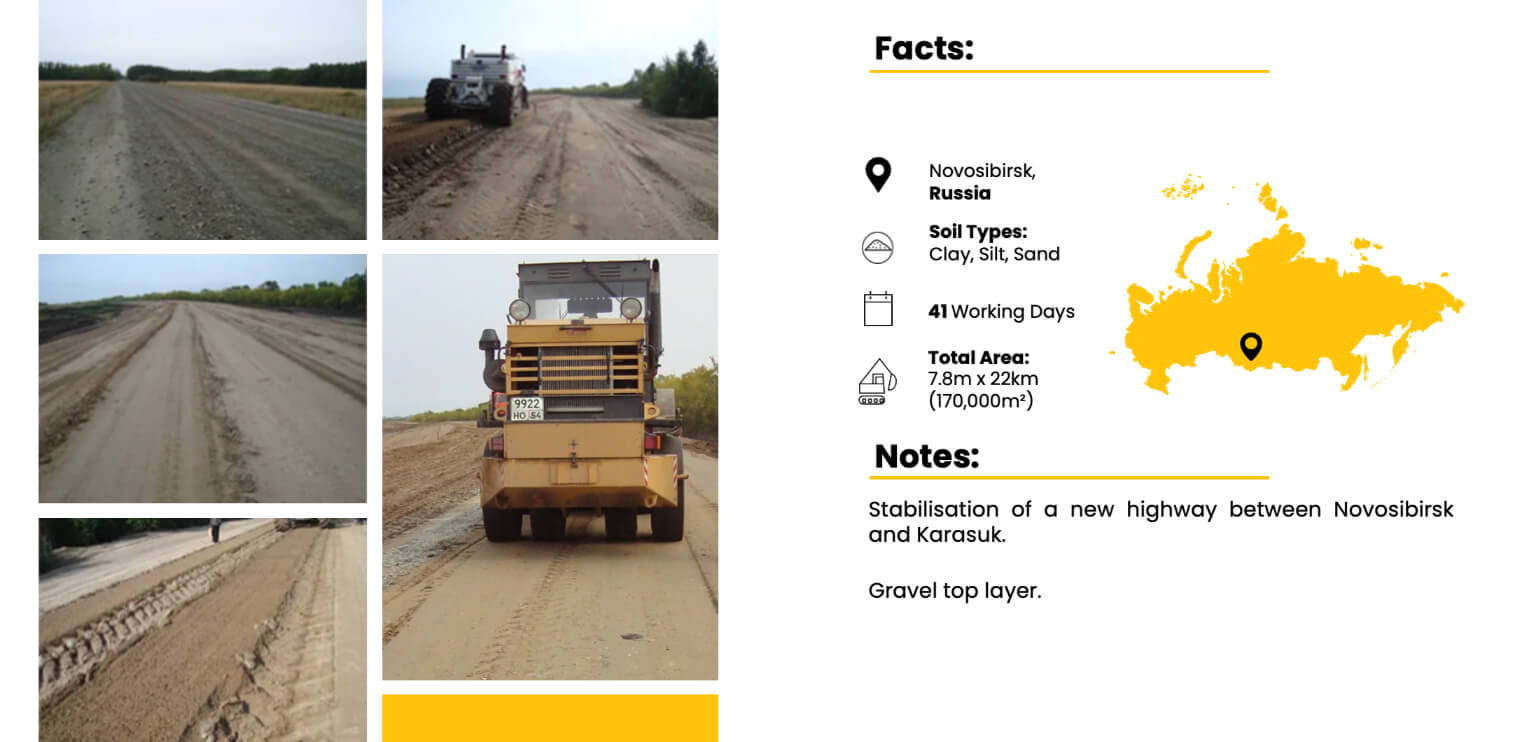

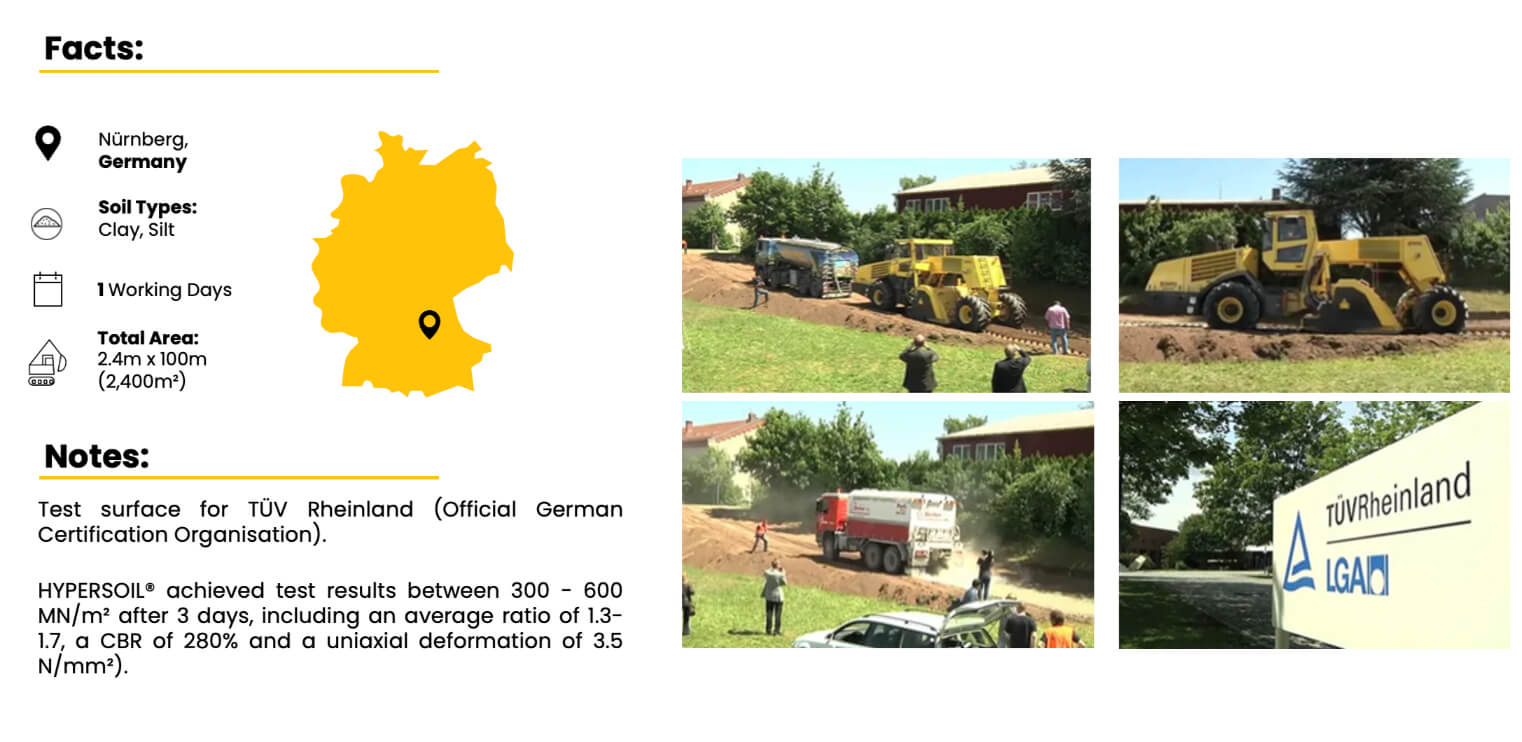

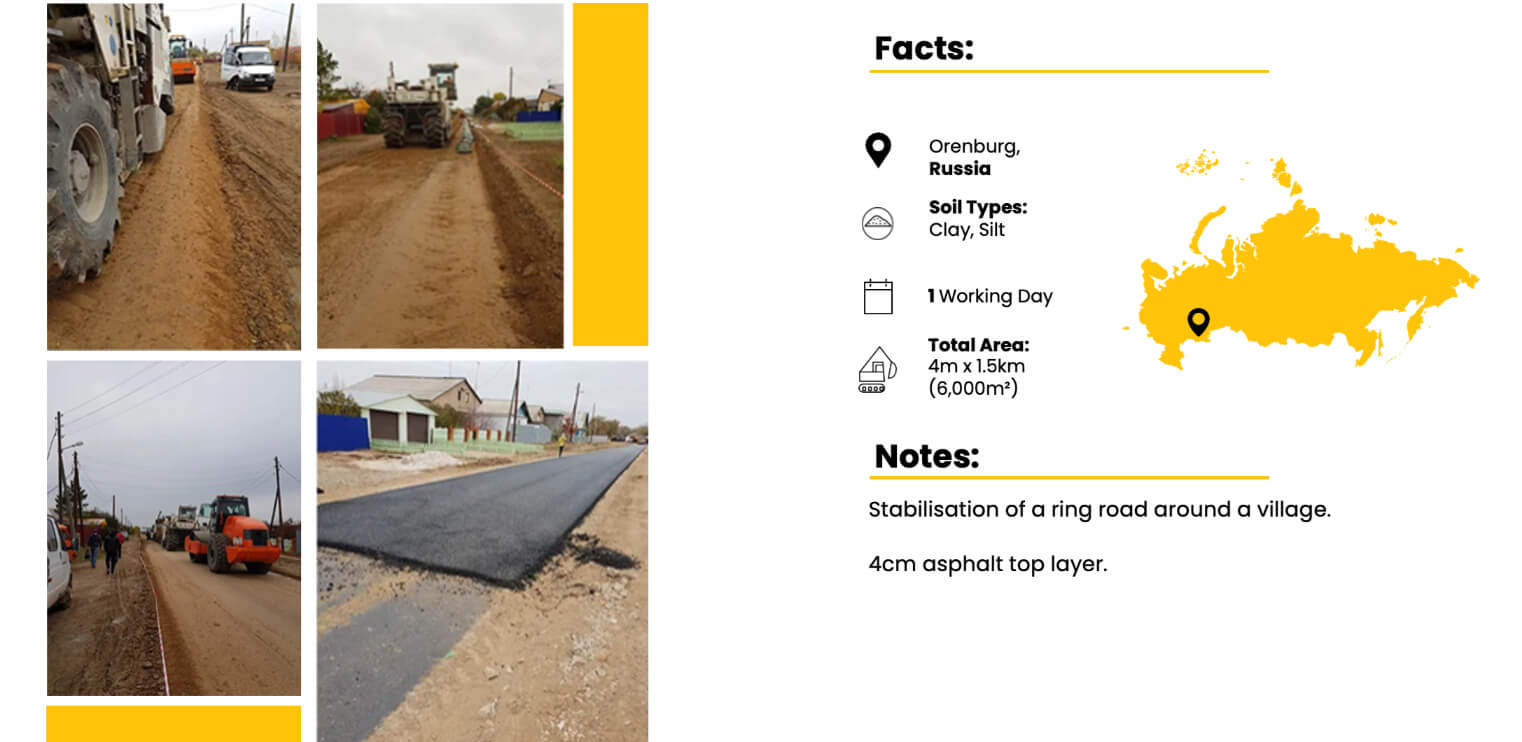

Projects